Beskrivelse:

H70 brunsten har ekstremt god plasticitet (den bedste blandt brunsten) og høj styrke, god bearbejdningsevne, nem at vende, og er meget stabil overfor almindelig korrosion, men er underlagt korrosionsrådning

Anvendelser:

Det er en industribruk brunsten brugt til varmevekslere, papirrør, maskiner og elektronikkomponenter.

Specificerings:

1.C2600 H70 Kemisk sammensætning (%):

| GB | Cu | F | Pb | af | Samlet mængde af ukedigheder |

| H70 | 68,5-71,5 | ≦0. 1 | ≦0. 03 | residual | ≦0. 3 |

2.C2600 Kemisk sammensætning (%)

| JIS | Cu | F | Pb | af |

| C2600 | 68,5-71,5 | ≦0. 05 | ≦0. 05 | residual |

3.C2600 H70 Coil mekaniske egenskaber: GB/T 2059-2017

| C2800Slange | Trækstyrke RmMPa | Forlængelse A11. 3% | Hårdhed | Status af materiale |

| ≧0. 2mm | ≧290 | 40 | ≦90 | O60 |

| 325-410 | ≧35 | 85-115 | H01 | |

| 355-460 | ≧25 | 100-130 | H02 | |

| 410-540 | ≧13 | 120-160 | H04 | |

| 520-620 | ≧4 | 150-190 | H06 | |

| ≧570 | -- | ≧180 | H08 |

4.C2600 H70 Plade Mekaniske egenskaber: GB/T 2040-2017

| C2800 Plade | Trækstyrke RmMPa | Forlængelse A11. 3% | Hårdhed | Status af materiale |

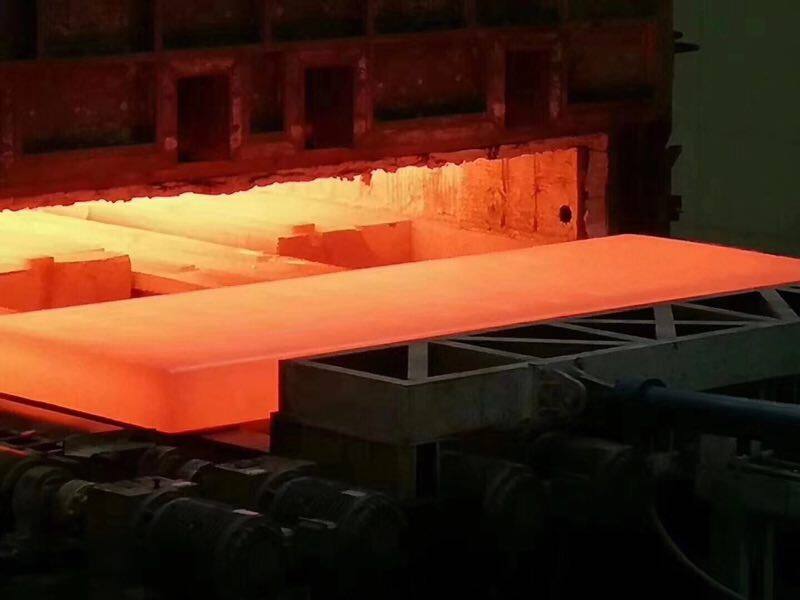

| ≧20mm | Varmerulle | M20 | ||

| 0,2-20mm | ≧290 | 40 | ≦90 | O60 |

| 325-410 | ≧35 | 85-115 | H01 | |

| 355-460 | ≧25 | 100-130 | H02 | |

| 410-540 | ≧13 | 120-160 | H04 | |

| 520-620 | ≧4 | 150-190 | H06 | |

| ≧570 | -- | ≧180 | H08 | |

Vores venlige team vil meget gerne høre fra dig!