Miedź to unikalny metal, który wykonuje różne zadania dla wielu ludzi. Szeroko stosowana jest do rurek, przewodów elektrycznych i instalacji sanitarnej dzięki pewnym wybitnym właściwościom. Miedź jest ekstremalnie przewodząca, co pomaga w przepływie prądu. Może wytrzymać wysoką temperaturę bez pęknięcia i łatwo się kształtuje w różne formy. To główna przyczyna, dlaczego tak wiele branż wybiera miedź. Co do rozwoju blach miedzianych, istnieją dwa główne procesy: Walcowanie Gorące i Walcowanie Zimne. W tym artykule omówimy różnicę między oboma metodami oraz jak każdy z nich wpływa na wygląd i funkcjonalność blach miedzianych.

Jak proces produkcji blach miedzianych przekształca je

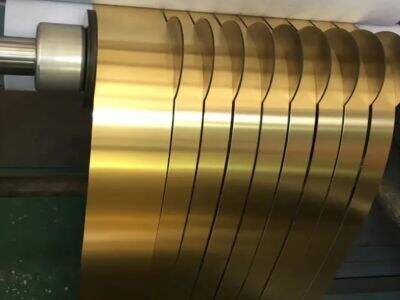

Jednakże, proces produkcji, który determinuje, jak dokładnie tworzymy płyty miedziane, jest kluczowy dla mikrostruktury, która z kolei może znacznie wpływać na ich właściwości fizyczne i mechaniczne. W przypadku walcowania ciepłego najpierw grzejemy miedź do temperatury, która jest znacznie wyższa niż można by oczekiwać. Następnie przepuszczamy ją przez duże wały, które ją spłaszczają i wyciągają, gdy osiągnie odpowiednią temperaturę. Te płyty miedziano-aluminiowe są produkowane za pomocą procesu walcowania ciepłego, co czyni je lżejszymi (niższa gęstość). Jednakże ich powierzchnia ulega utlenianiu, dlatego mają inny wygląd niż inne płyty miedziane. Walcowanie zimne to zupełnie inna sprawa. Termin „zimno-walczony” oznacza, że miedź jest walcowana przy temperaturze otoczenia, czyli daleko od gorąca. Jest to metoda wzmacniania płyt miedzianych i nadawania im gładkości z mniejszym stopniem utleniania. Ze względu na te różnice w działaniu walcowania ciepłego i zimnego, wytrzymałość płyt miedzianych walcowanych ciepło jest zwykle niższa niż tych, które zostały walcowane zimno.

Wpływ temperatury na wygląd i siłę blasz miedzianych

Blachy miedziane, takie jak połyskująca blacha miedziana są bardzo wrażliwe na proces ich produkcji, ponieważ każda niewielka zmiana temperatury obiecuje widoczne różnice w wyglądzie i sile tych blasz. Ponieważ ciepłe walcowanie tworzy solidny gładki efekt, takie blachy są grube i względnie charakterystyczne. Jest to bardzo zależna od ciepła sprawa, która może zmienić twardość i wytrzymałość blachy miedzianej. W przeciwieństwie do tego, blachy miedziane zimno-walceowane są produkowane przy temperaturze pokojowej, dlatego mają gładką powierzchnię. To właśnie ta gładkość, razem z mniejszą ilością utleniania występującego podczas zimnego walcowania, czyni blachy miedziane zimno-walceowane bardziej odpornymi i trwałości.

Jak wybrać odpowiednią metodę dla siebie?

Procesy, które używasz dla swoich płyt miedzianych, zależą od tego, do czego je potrzebujesz. Jeśli jednak potrzebujesz płyt miedzianych do zastosowań, w których musi przepływać duży prąd, płyty ciepłe będą idealne. Są one wykorzystywane we wszystkich formach zastosowań elektrycznych, takich jak motory, przewody i transformatory. Te kwadratowe płyty miedziane są również odpowiednie dla systemów HVAC, które wymagają wysokiej przewodności cieplnej. Płyty miedziane w postaci taśmy są również walcowane ciepło, aby ułatwić przepływ elektryczności. Jednakże, jeśli Twój projekt wymaga tylko falistej powierzchni, lub jeśli nie potrzebujesz dokładności wymiarów, zimno-walcowane płyty miedziane będą dla Ciebie lepszym rozwiązaniem. Używane płyty są zazwyczaj stosowane w pracach architektonicznych, panelach dachowych i przedmiotach dekoracyjnych. Inną zaletą zimno-walcowanych płyt miedzianych jest to, że ich siła nie maleje przy niskich temperaturach.

Różnica między płytą miedzianą walcowaną ciepło a walcowaną zimno V++

Więc w ciągu lat ludziom łatwo odróżnić płyty miedziane wytworzone metodą ciepłego lub zimnego walcowania ze względu na różne lub wrodzone cechy. Płyty miedziane walcowane cieplnie są względnie duże i lekkie, a ich powierzchnia odbijająca jest stosunkowo błyszcząca, co może prowadzić do mylnych wniosków. W międzyczasie, płyty miedziane walcowane zimno są duże, ale ciężkie i mają teksturę bardziej jednolitą i gładką. Ich proces produkcji wpływa na ich wygląd, elastyczność i skończenie ich powierzchni.

Podsumowując, sposób produkcji płyt miedzianych jest rzeczywistą opcją i powinien zależeć od tego, do czego potrzebujesz ich używać. Płyty miedziane wykute w temperaturze wysokiej posiadają unikalną strukturę dobrze acompañającą zastosowania wymagające doskonałej przewodności cieplnej lub innych specjalistycznych przypadków użycia. Z drugiej strony, płyty miedziane zimnociśnieniowe są gładkie i mają większą wytrzymałość w porównaniu z wykutymi w temperaturze wysokiej, zwłaszcza w warunkach niskich temperatur. Dedykujemy się produkcji różnych rodzajów płyt miedzianych najwyższej jakości za pomocą różnych metod produkcyjnych, które spełniają wymagania naszych klientów w Huansheng Alloy Technology. Nasze płyty miedziane mają wzorcowe właściwości i solidne wykonanie, co z kolei pozwala im dobrze funkcjonować we wszystkich zastosowaniach, w których są używane.

EN

EN