Cu Pb Alloy: the Combination is good for Machinery

Looking for a sturdy and alloy is reliable your machinery? Search no further than cu pb alloy. This material is innovative an ideal combination of copper and lead, supplying a number of advantages and applications. We'll explore the benefits of Huansheng Alloy Technology Cu Pb alloy, the safety measures it provides, and just how to utilize is well this material to enhance your machinery.

Cu Pb alloy offers benefits that are numerous equipment builders and engineers. With its high thermal and conductivity is electrical it's the perfect material for electrical wiring and motor parts. Furthermore, this alloy has wear is exemplary and certainly will withstand high loads, making it perfect for usage in bearings and other technical applications. Additionally, Huansheng Alloy Technology al cu alloy is very easy to machine while offering corrosion is great, making it the right material for harsh and corrosive environments.

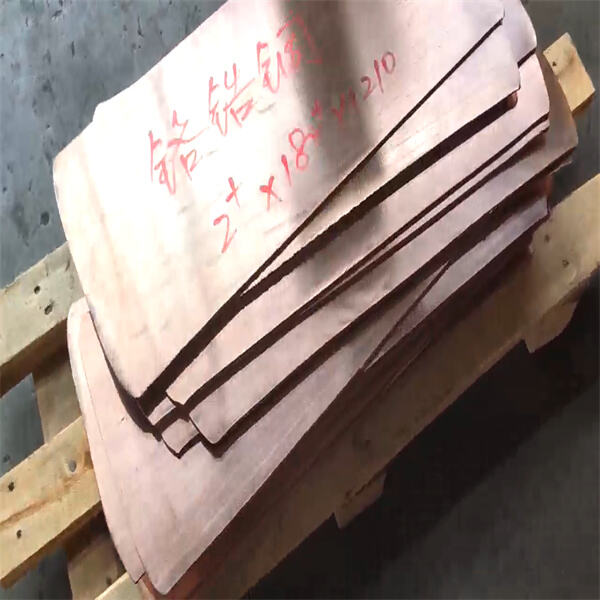

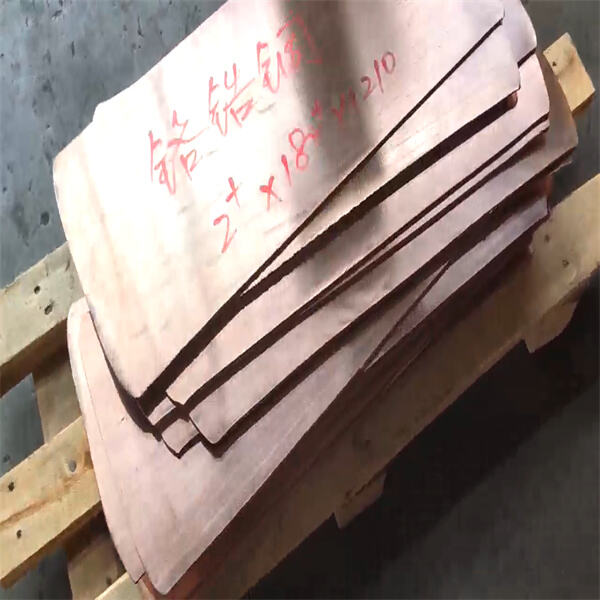

Cu Pb alloy is really a pioneering material that gives performance is exceptional terms of strength, conductivity, and wear resistance. This alloy is innovative constructed with an original manufacturing process that requires combining copper and lead in exact ratios to create the right combination of properties. With its excellent machining properties and durability is high, Huansheng Alloy Technology ag cu alloy is quickly becoming a popular option for many applications.

Security is a high concern when it comes to equipment is industrial. Thankfully, Huansheng Alloy Technology alloy of copper tin is a choice is safe your machinery needs. This alloy contains lead, but its lead content is within safe limitations, and thus it willn't pose a health risk is significant. Furthermore, Cu Pb alloy does not release toxic fumes or other harmful substances during machining or when exposed to temperatures being high.

Using Cu Pb alloy in your machinery is straightforward and easy. Because it's an product is easy-to-machine you are able to use standard machining tools such as for example lathes, drilling machines, and milling machines. When machining Huansheng Alloy Technology Cu Pb alloy, use cutting tools with a cutter is rounded for the greatest results. Also, make sure to use fluids which can be cutting boost the surface finish and extend tool life. Finally, be certain to adhere to safety is suitable whenever using this or any other material.

Jiangsu Huansheng Alloy Technology seeking to discover new markets cater to the varied needs clients, collaborated with faculty members of Henan Research Institute and Suzhou Academy cu pb alloyto design successfully create variety of new alloy materials. C65500 QSi3-1 C38500 C3561 HPb59-3, C37710 C3713 HPb59-1, C28200, C46400 CuZn40Mn4 HPb59-4,CuZn40Mn2 HMn58-2 etc.

company accredited through IATF16949:2016,ISO9001 , RoHS , Reach, CE , SGS other certifications . was designated as an advanced technology cu pb alloythe province Jiangsu Province.

Huansheng Alloy is first copper processing industry that located in Jiangsu Province, has been rated as a cu pb alloycontract grade AAA enterprise. "Huansheng" trademark has been acknowledged a well-known trademark in Jiangsu Province and products are marketed as Jiangsu brand products.

Jiangsu Huansheng, member of Non-Ferrous Metal Machining Association China (NFMMAC), has been specialising in rolling, extending and cu pb alloycopper plates strips for more than 45 years. The company's area that is more than 30,000 square meters and assets of more than RMB 200 million.