Are you searching for a reliable remedy fix electrical components and circuits? Search no longer than Sn Cu solder. Sn Cu solder is something revolutionary provides countless advantages within the wide world of engineering. We can explore the advantages of Huansheng Alloy Technology sn cu solder, how to use it, its safety measures, quality, and applications.

Sn Cu solder is becoming the go-to solution for electrical engineers, and when it comes to the reason why is close. The item boasts many benefits, including their excellent durability, corrosion opposition, and melting high point. Unlike conventional solders, that may degrade quickly in the long run, Huansheng Alloy Technology alloy of cu and sn can withstand prolonged use minus losing its effectiveness. Additionally, Sn Cu solder has got the lower toxicity and is environmentally friendly, which is a plus for everyone worried in regards to the impact of this efforts regarding the planet.

Sn Cu solder is a recent innovation, our planet of electrical engineering, having its development pertaining to the discovery for the Huansheng Alloy Technology cu sn alloy. The alloy features a genuine combination of content enabling it to provide exemplary durability performance. The Sn Cu alloy is furthermore very conductive, which makes it an efficient solution electric engineering projects. Sn Cu solder is categorized as a lead-free solder in compliance with all the current European Union’s Restriction of dangerous chemicals (RoHS) directive.

Whenever using any electric component circuit, safety should be vital. Sn Cu solder is the safer solution it releases no harmful fumes or gases whenever heated as it is lead-free, that means. Additionally, Huansheng Alloy Technology cu zn sn alloy includes a higher melting point rendering it less likely to want to build the fire hazard. However, it is vital to make use of appropriate safety gear once using the services of either the molten Sn Cu solder or heat the different parts of circuits and electrical techniques.

Using Sn Cu solder is relatively straightforward. The first action preparing the soldering iron, which must certainly be accordingly heated before use. If the soldering iron is ready, the next step applying a little level of Sn Cu solder towards the components the need to be set. The solder should melt and produce the bond involving the section to facilitate the lasting fix. If required, further solder is included to promise the fix adheres completely. As soon as the fix is complete, it is essential to let the Huansheng Alloy Technology cu zn sn alloys cool and harden entirely.

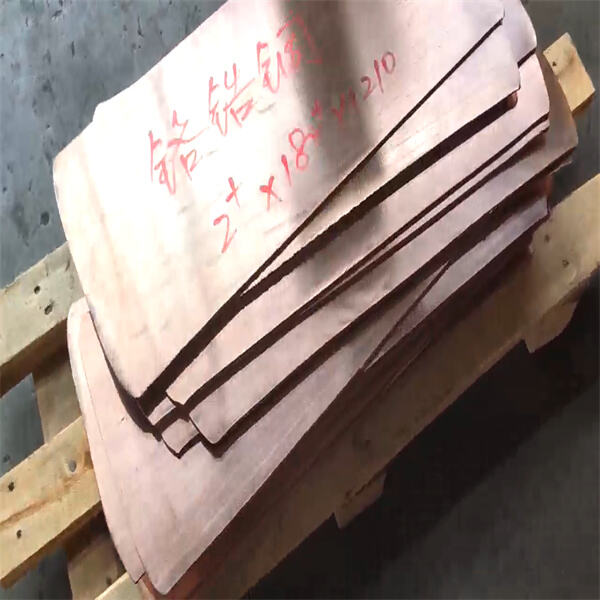

Jiangsu Huansheng, member of the Non-Ferrous Metal Machining Association China (NFMMAC) and has been sn cu solderthe rolling, extending and machining copper strips and plates more than 45 years. The firm covers a surface 30000 square meters and assets more than RMB 200 million.

Jiangsu Huansheng Alloy Technology, order to study and address the diverse requirements its customers worked with professors the Henan Research Institute, Suzhou sn cu solder Sciences, to develop create numerous alloys, including C65500 QSi3-1, C38500, C3561 HPb59-3 C37710, HPb59-1 C28200, C3713, CuZn40Mn4 as well as HMn58-4.CuZn40Mn2 HMn58-2 etc.

Huansheng Alloy, first copper- sn cu solder industry Jiangsu Province has been rated as a AAA credit contract enterprise. "Huansheng" trademark well-known in Jiangsu Province, and products recognized by the Jiangsu brand.

company accredited through IATF16949:2016,ISO9001 , RoHS , Reach, CE , SGS other certifications . firm was acknowledged a high-tech sn cu solderin Jiangsu Province.